HPAS | Aluminium Specialized End Mills

The HPAS line of Aluminium Specialized End Mills is meticulously engineered to meet the demanding requirements of modern aluminium machining. Developed by Palbit with a deep understanding of the challenges associated with cutting aluminium alloys, this range is purpose-built to deliver outstanding performance, productivity, and surface quality across a variety of operations.

Aluminium machining presents unique obstacles, such as material adhesion, long chip formation, and thermal distortion – all of which demand cutting tools with specific geometries, coatings, and flute designs. The HPAS line addresses these needs through advanced engineering, offering solutions that ensure optimal chip evacuation, high material removal rates, and excellent dimensional accuracy.

With tailored designs for different machining strategies – from roughing to finishing, flat surface cutting to 3D profiling – the HPAS portfolio covers a wide range of applications in industries such as aerospace, automotive, mould & die, and general engineering.

Its diverse geometries empower machinists to overcome process limitations while achieving the high precision, efficiency, and consistency expected in today’s competitive manufacturing landscape.

HR35HPAS | Corner Radius End Mill

■ Unequal pitch to minimize vibrations

■ Robust cutting edge for high material removal rates

HF45HPAS | Flat Top End Mill

■ Precision-ground cylindrical edge to minimize chatter and vibration

■ Polished w flute shape for efficient chip evacuation

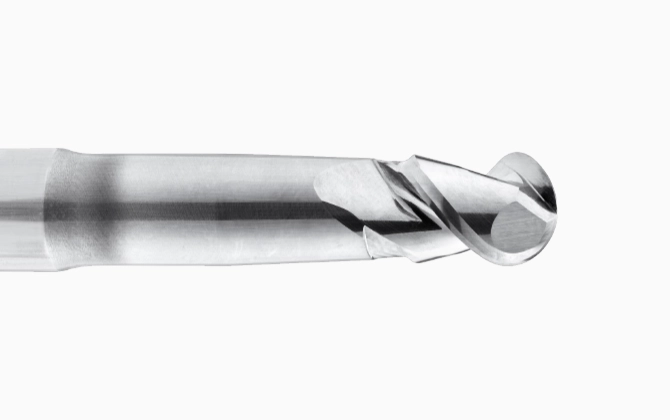

HB50HPAS | Ball Nose End Mill

■ Reduced neck strengthens deep and long-reach cuts

■ High helix geometry enables high-performance shearing

Aluminium Specialized End Mills

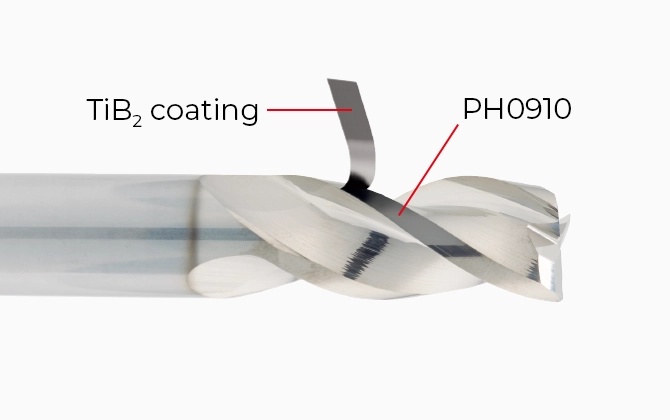

PHT Coating

The coating’s nanocrystalline, ultra-dense, and exceptionally smooth PVD-deposited structure ensures optimized adhesion to the substrate, combining superior hardness with excellent thermal stability. This powerful combination not only extends tool life but also enables higher cutting speeds and feeds, resulting in improved process reliability, reduced downtime, and maximum productivity.

Moreover, PHT’s resistance to oxidation and wear makes it ideal for applications involving elevated temperatures and challenging machining conditions, guaranteeing consistent, high-quality surface finishes and cost-efficient manufacturing.

PHT910 FEATURES

■ Excellent protection against built-up edges

■ Provides maximum lubricity and tool life

■ Top performance on aluminium applications

Main features of HPAS line:

■ Polished flutes ensure efficient chip evacuation with minimal friction

■ PHT coating prevents adhesion due to its low affinity for aluminium

■ Long tool life with excellent surface finish and low energy consumption

Where innovation meets aluminium machining excellence

Challenges of Machining Aluminium

Machining aluminium alloys is generally easier than machining metals such as steel or stainless steel, thanks to aluminium’s lower density and excellent machinability. However, several challenges can arise that require attention to ensure a productive solution.

Here are some common difficulties in machining aluminium alloys:

■ Built-up edge (BUE):

■ Chip control:

■ Thermal expansion:

■ Tool wear:

Palbit’s new HPAS end mill line is the ideal solution to these challenges.

Machining Processes

SHOULDER MILLING

POCKET MILLING

SLOT MILLING

SLOT MILLING

(Curved)

WALL FINISHING

PROFILING

FACING

Product Range