Superior finish on 3D complex surfaces

W-PRO 62090

The design allows users to position the insert consistently, with the same side always facing the same direction when mounted in the tool body. This ensures high repeatable accuracy, reliability, excellent surface quality, and predictable tool life.

Now with a New Coating and Geometries,

find more!

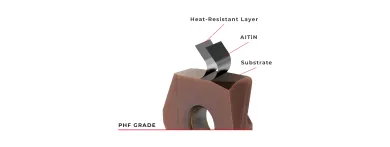

Introducing PHF Grade | New coating

Keeping our commitment with high performance cutting tools, we present our new PHF series of grades.

The PHF coating introduces significative enhancements when machining hard and exotic materials due to the better thermal stability, micro hardness and excellent adhesion, thus enhancing process stability and efficiency when machining hardened steels.

Hardened steels with a hardness greater than 50 HRC are not only extremely hard but also exhibit a certain level of toughness. Additionally, they often contain alloying elements that enhance corrosion resistance, making their machining more challenging. PHF series was specifically developed to face the challenge of machining these hardened steels.

With harder materials, the temperatures achieved during the machining process are also higher, raising as essential needs for the inserts, durable and heat-resistant coatings. PHF series provides excellent thermal insulation, preventing heat from reaching the tool and efficiently dissipating it through the chips.

Key Benefits of the PHF Coating

■ Originally developed for machining hardened steels (over 50 HRC), it also demonstrates versatility with stainless steels, nickel-based alloys, titanium, and standard steels;

■ High-density coating with improved adhesion to any tool geometry, and reduced roughness;

■ Heat-resistant layer for exceptional thermal stability and hardness;

■ Prevents heat from affecting the tool, crucial for materials with poor heat conductivity;

■ Improves chip removal, contributing to high process stability;

■ High temperature is dissipated through the chip, preserving tool integrity and performance;

■ Particularly successful in machining injection moulds.

WCX Inserts | Meet the New Geometries

-HF, -XT & -LE Chipbreakers

With the introduction of new tangential, barrel and lens inserts, the W-PRO line is optimized for 5-axis machining of complex 3D surfaces and profiles, making it ideal for the mould & die and aerospace industries.

These advanced inserts are designed with larger radius cutting edges compared to traditional ball nose inserts, allowing for greater stepover or stepdown increments during machining. This results in significantly improved productivity while maintaining high-quality surface finishes, making the W-PRO an ideal choice for precision finishing operations on intricate geometries.

The WCX-XT and WCX-LE inserts are available in the PHF910 grade. This new coating offers high wear resistance due to the latest PVD coating technology, ensuring that the PHF910 provides exceptionally long tool life.

WCR

WCL

WCX-XT NEW

WCX-LE NEW

WCX-HF NEW

Wall Finishing

High Feed Roughing

Surface Finishing

Product Range