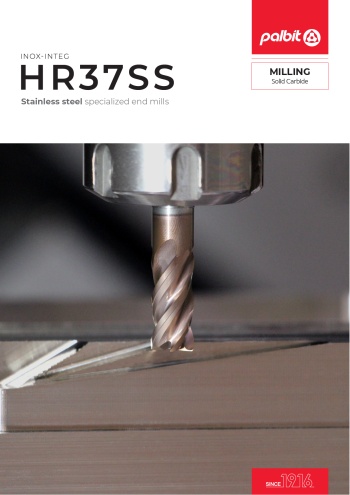

Stainless Steel Specialized End mills

INOX-INTEG | HR37SS

The HR37SS solid carbide end mill is specifically engineered to overcome the challenges of machining stainless steel, ensuring exceptional performance across a broad range of applications. Featuring a newly developed four-edge corner radius geometry, it delivers enhanced multi-functional performance, from roughing to finishing operations.

Designed to address the unique difficulties of stainless steel - such as high work hardening, shear resistance, chip adhesion, and elevated machining temperatures - it incorporates a high-toughness substrate and advanced coating for superior wear resistance and chip adhesion prevention. Additionally, the optimized cutting edge reduces cutting loads, minimizes chatter, and prevents unexpected chipping, ensuring consistent and efficient machining performance.

Features and Benefits

■ High performance in stainless steels;■ Complex flute geometry for superior surface quality;

■ Strong cutting edge with excellent chipping resistance;

■ Reliable machining performance up to 2xDC;

■ High angles in ramp and helical interpolation, up to 15º;

■ Suitable for dynamic trochoidal milling;

■ PHF coating for application temperatures up to 1100° C;

■ PHF920 grade for durability and wear resistance;

Stainless steel machining just got easier.

Meet the HR37SS Solid Carbide End Mill, designed to handle it all.

Stainless Steel Machining Challenges and how the HR37SS End Mill solves them

Machining stainless steel is no easy feat. Its unique properties often make it challenging to work with, requiring advanced tools and techniques to achieve consistent and high quality results.

High Cutting Force and Temperature

Optimized cutting edge geometry that reduces cutting forces and efficiently dissipates heat. In addiction, the PHF coating provides exceptional thermal stability, reducing tool degradation caused by high temperatures.

Hardening During Machining

High toughness substrate that withstands the stress of hardened material zones. Its improved edge stability ensures consistent cutting performance, even in challenging conditions.

Chip Adhesion to Tools

The advanced PHF coating prevents chip adhesion and fusion welding, keeping the cutting edge clean while the 4-edge corner radius design improves chip flow and ensures a smooth, high quality surface finish.

Accelerated Tool Wear

The wear resistant PHF coating extends tool life by reducing wear caused by high temperatures and friction. The high toughness substrate adds durability, minimizing the need for frequent tool changes and increasing overall productivity.

Machining Processes

SHOULDER MILLING

FINISHING MILLING

HELICAL INTERPOLATION

POCKET MILLING

FINISHING MILLING

SLOT MILLING

PLUNGE MILLING

RAMP MILLING 7.5º

RAMP MILLING 15º

RAMP MILLING 30º

Product Range