Indexable Inserts and Solid Ceramic End Mills

CERABOOST

Nickel-based superalloys are valued for their exceptional high-temperature strength, structural reliability and resistance to corrosion and fatigue, making them ideal for engineering components subject to high thermo-mechanical loads, particularly in the aerospace industry. However, their remarkable properties result in poor machinability, which limits processing efficiency. Challenges include high shear strength, tendency to work hardening, abrasive carbide precipitates and extreme temperatures at the tool-chip interface.

In addition, low thermal conductivity impedes heat removal, while the material’s high weldability causes built-up edge on cutting tools, further complicating machining operations and requiring advanced cutting technologies to improve performance and efficiency.

Palbit’s CERABOOST range combines advanced ceramic technology with optimised geometry to deliver outstanding performance and eff iciency in nickel-based alloys, from roughing to semifinishing.

The CERABOOST range of milling tools includes ceramic indexable inserts and solid ceramic end mills. They are designed to meet the different requirements of superalloys machining.

Introducing CERABOOST Products

INDEXABLE CERAMIC INSERTS

High-performance ceramic milling solution, offering stable, high-speed machining with versatile insert geometries.

CERABOOST 44090 | RPGN 0602: Diameter Ø16 and Ø20mm

CERABOOST 44190 | RPGN 0903: Diameter Ø25 and Ø32mm

CERABOOST 44290 | RPGN 1204: Diameter Ø32, Ø40 and Ø50mm

CERABOOST 44590 | RPGN 1207: Diameter Ø50, Ø63 and Ø80mm

SOLID CERAMIC END MILLS

End mills that combine an advanced substrate with a unique cutting geometry for enhanced productivity.

CERABOOST CR42SS: Diameter Ø6 to Ø16mm

Round Inserts

Positive or negative inserts.

Shank Type

With threaded or arbor mounting to enable both small and large cutting diameters.

Clamp System

Wedge or screw clamp to ensure quick and easy indexing.

Coated Inserts

To reduce material adhesion.

Robust Core

75% of the cutting diameter.

High Performance Substrate

High heat resistance for high speed machining.

Optimized Flute Geometry

For smooth chip evacuation.

Redefining machining excellence

with advanced ceramic solutions for challenging materials.

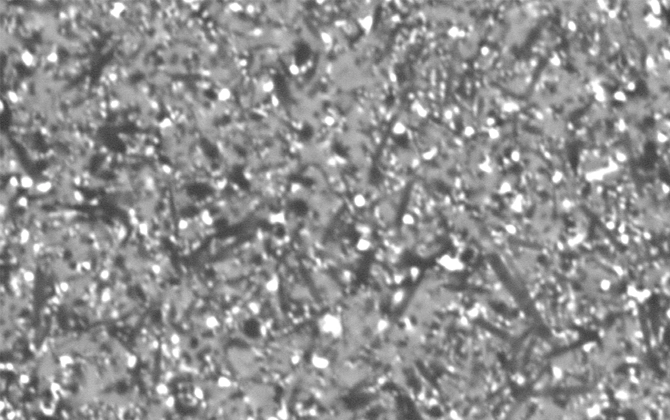

Ceramic Grades

Primarily composed of alumina (Al₂O₃) or silicon nitride (Si₃N₄), ceramic tools are tailored to meet specific requirements through the use of different grades and additives. These tools excel in high-speed machining and extreme environments, offering superior performance and high material removal rates compared to traditional materials, making them a preferred choice for demanding applications.

Key Benefits of the Ceramic Grades

■ Excellent heat resistance;■ High hardness;

■ High wear resistance;

■ Excellent chemical stability;

■ Dry machining;

The PCN010 grade, when coated, becomes the PCNY10 grade, offering several key benefits. These include easy wear detection, a low coefficient of friction, reduced material adhesion, and more stable wear progression.

Unveiling the layers

Top Coating (TiN)

Doped Layer

Inner Coating (TiAIN)

Substrate

Machining Processes

FACE MILLING (Roughing)

SHOULDER MILLING

TROCHOIDAL MILLING

CONTOUR MILLING

FACE MILLING (Finishing)

Product Range