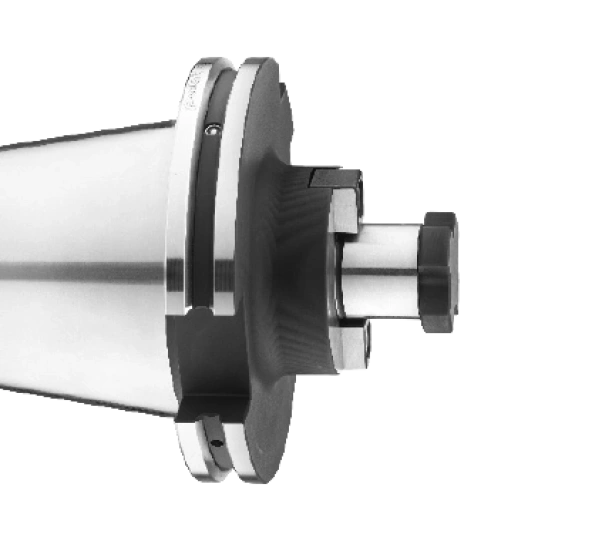

Precision and Performance in Every Clamping

Tool Holding Solutions

Palbit continues to expand its product range to meet the evolving demands of precision machining. Committed to high-quality tooling solutions, we now offer a comprehensive selection of tool holding solutions designed for superior performance and reliability.

Engineered with high-precision standards, our holders ensure stability, accuracy, and durability in demanding applications. With optimized designs they minimize run-out, enhance tool life, and improve machining productivity.

This new range complements our existing portfolio, providing a complete solution for high-performance operations. Whether you require enhanced rigidity, superior clamping force, or high-speed capabilities, our toolholders consistently deliver optimal results across various applications.

Don't miss the oportunity and ask us how we can help you

to maximize your productivity!

MACHINE CONNECTION

SK Steep Taper Holders

Designed for high-precision machining, SK holders provide excellent stability and strength, making them ideal for general applications.

Their steep taper design ensures firm tool clamping and high torsional rigidity.

Cost-effective and robust, SK holders are perfect for demanding environments, where rigidity and durability are crucial.

BT MAS-BT Holders

TOOLHOLDER CONNECTION

The following toolholder types are available for ISO 7388-1, ISO 7388-2, and 12164-1 HSK systems:

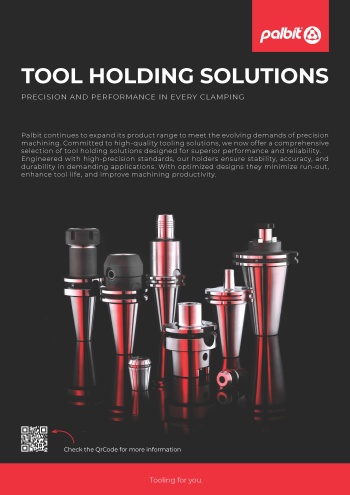

COLLET CHUCKS for collets ISO 15488 (DIN 6499) ER-system

END MILL HOLDERS DIN 6359 for end mills DIN 1835-B

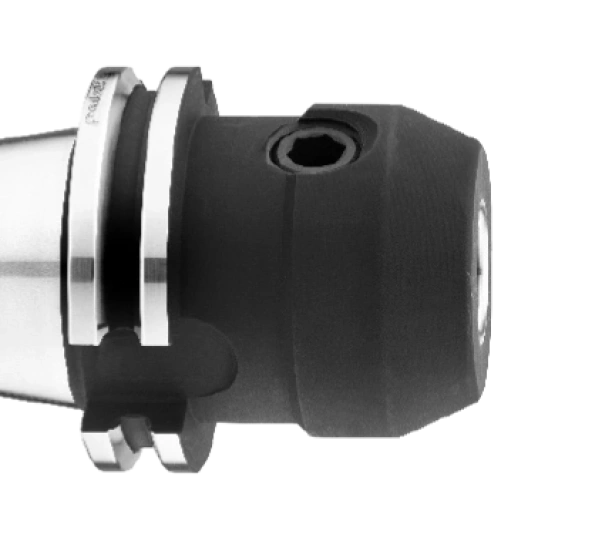

SHELL MILL HOLDERS DIN 6357

MILLING ARBORS for screw-in cutters

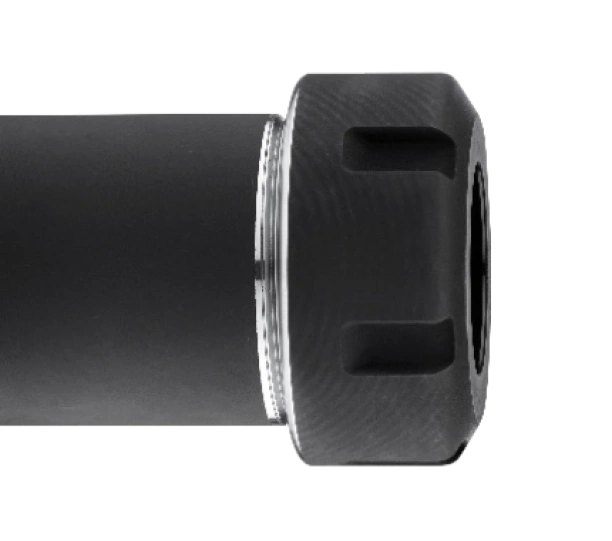

HYDRAULIC EXPANSION CHUCKS

SHRINK CHUCKS 4.5°

Precision and Performance

in Every Clamping

TOOLHOLDERS ISO 7388-1 SK (DIN 69871)

Collet chucks for collets ISO 15488 (DIN 6499) ER-system

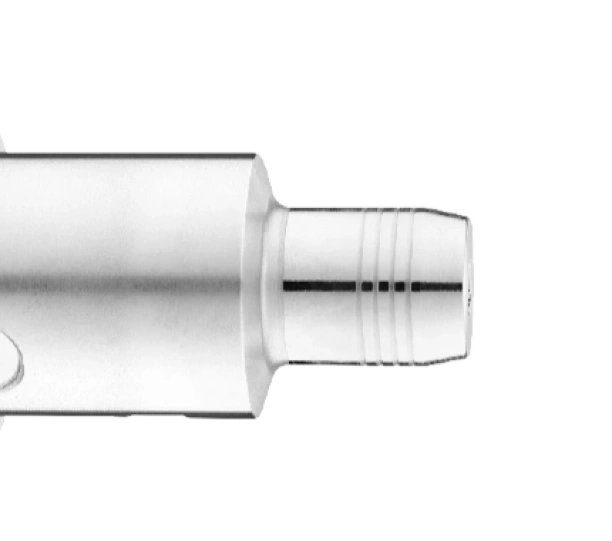

END MILL HOLDERS DIN 6359 for end mills DIN 1835-B

SHELL MILL HOLDERS DIN 6357 with enlarged contact face and coolant exit bores on the end face

MILLING ARBORS for screw-in cutters

HYDRAULIC EXPANSION CHUCKS

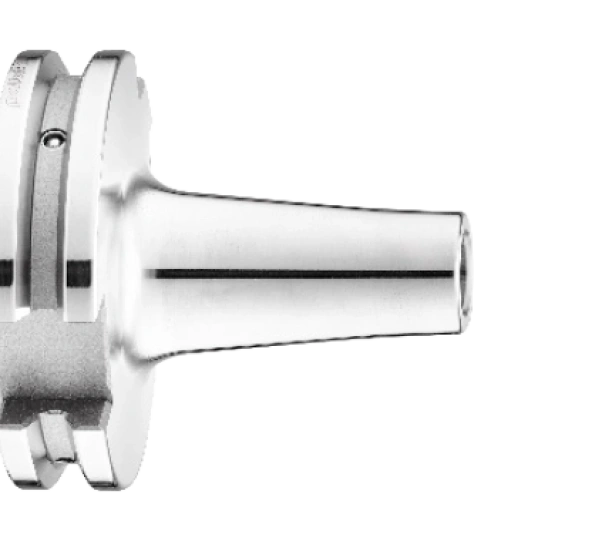

SHRINK CHUCKS 4.5° for mounting of solid carbide and HSS-tool shanks

TOOLHOLDERS ISO 7388-2 BT (JIS B 6339 MAS-BT)

Collet chucks for collets ISO 15488 (DIN 6499) ER-system

END MILL HOLDERS DIN 6359 for end mills DIN 1835-B

SHELL MILL HOLDERS DIN 6357 with enlarged contact face and coolant exit bores on the end face

MILLING ARBORS for screw-in cutters

HYDRAULIC EXPANSION CHUCKS

SHRINK CHUCKS 4.5° for mounting of solid carbide and HSS-tool shanks

TOOLHOLDERS ISO 12164-1 HSK (DIN 69893 HSK)

Collet chucks for collets ISO 15488 (DIN 6499) ER-system

END MILL HOLDERS DIN 6359 for end mills DIN 1835-B

SHELL MILL HOLDERS DIN 6357 with enlarged contact face and coolant exit bores on the end face

MILLING ARBORS for screw-in cutters

HYDRAULIC EXPANSION CHUCKS