Precision and accuracy with solid carbide end mills

What are solid carbide end mills?

Solid carbide end mills are available in a wide range of lengths, diameters, and geometries. These characteristics are defined according to the material to be machined, the operation to be carried out and the type of surface finish required.

Due to the high precision requirements of the applications, this type of milling solution is produced using computerized machines. The solid carbide end mills are previously designed in software and imported into the machine. Through diamond grinding wheels that are mounted on the spindles of the machine, the geometry of the solid carbide is given. The coating of the solid carbide solutions increase their useful life.

Solid carbide end mills achieve unparalleled cutting performance, have a long tool life and enable the production of demanding parts in industrial sectors such as aerospace, medical, mold & die and energy.

Advantages of using solid carbide end mills

- Higher Tool Life

- Reduced Downtime

- Higher Speeds

- Surface Finish

- Rigidity

- Heat Resistance

Learn more about our solid carbide end mills range

Our RAD-INTEG for CAM software and 5 axis machining

Learn how to scale your productivity with our solid carbide end mills range

From ØDc 0,4mm to ØDc 20mm, for all aplications and to machining all tipes of materials, we have the answer. Let us know your needs, we will give you the solution.

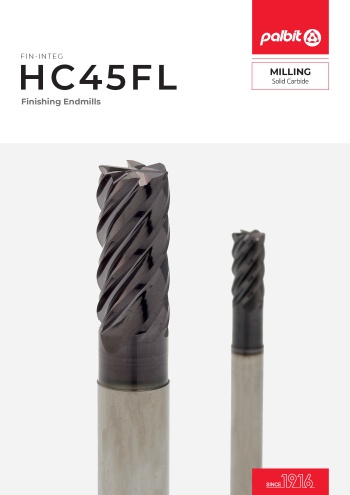

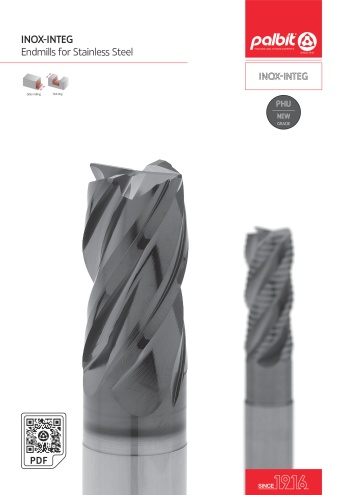

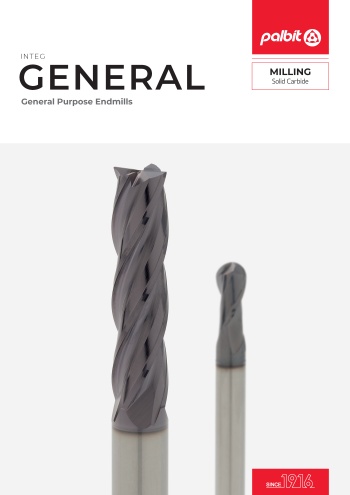

Products Range

![Solid Carbide End Mills Catalogue [INTEG] Solid Carbide End Mills Catalogue [INTEG]](https://www.palbit.pt/media/cache/350x495/uploads/Downloads Catálogos/Thumbnail-SolidCarbideEndMills.webp)