100 Years of Hardmetals

- 100 Years of Hardmetals/100-Years-of-Hardmetals-1110x420.webp)

Celebrating 100 years of cemented carbide and exploring the future of this revolutionary material in the age of sustainability.

On March 30th, 1923, a patent titled "Gesinterte harte Metallegierung und Verfahren zu ihrer Herstellung" (Sintered hardmetal alloy and production thereof) was filed under the number 420689 at the German Reichspatentamt, with the given inventor Karl Schröter in Berlin-Lichtenberg.

This patent, which claimed a composite material composed of tungsten carbide and iron, cobalt, and/or nickel, marked the beginning of the era of hardmetals or cemented carbides.

Cemented carbide has since revolutionized the manufacturing landscape, allowing for rapid machining, increased productivity, and reduced costs. One company that has played a crucial role in this journey is Palbit.

With a rich history of cemented carbide tool development, Palbit remains committed to pushing boundaries and driving innovation in the face of new challenges.

This patent, which claimed a composite material composed of tungsten carbide and iron, cobalt, and/or nickel, marked the beginning of the era of hardmetals or cemented carbides.

Cemented carbide has since revolutionized the manufacturing landscape, allowing for rapid machining, increased productivity, and reduced costs. One company that has played a crucial role in this journey is Palbit.

With a rich history of cemented carbide tool development, Palbit remains committed to pushing boundaries and driving innovation in the face of new challenges.

The Evolution of Cutting Tool Materials

Before cemented carbide, tool steel and high-speed steel were the primary materials used for cutting tools. However, their limitations in heat resistance and cutting speed led to the development and adoption of cemented carbide.

Cemented carbide tools revolutionized the manufacturing process, bringing about significant advancements in productivity and cost reduction across various industries.

Cemented carbide tools revolutionized the manufacturing process, bringing about significant advancements in productivity and cost reduction across various industries.

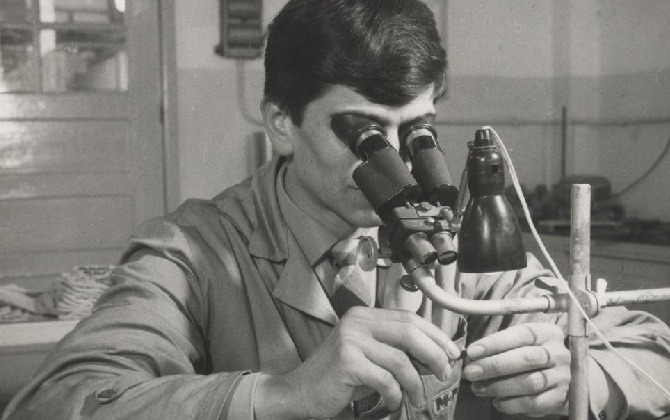

Palbit began its operations in 1916, initially focusing on the exploitation of lead sulfide mines in Palhal, Portugal, and the production and trade of hard metal tools.

Acquired by the SAPEC Group in 1941, Palbit expanded its mining operations to other mines within the group and increased its presence in the rock tools business area, producing mining drilling equipment and cutting tools.

In 1956, registered the trademark "Palbit," allowing the international path of the brand, previously known as "Minas e Metalurgia" (Mines and Metallurgy). This move marked the beginning of Palbit's pioneering path in the cemented carbide market. Since then, Palbit has continued to innovate, developing new grades and applications for cemented carbide tools.

Acquired by the SAPEC Group in 1941, Palbit expanded its mining operations to other mines within the group and increased its presence in the rock tools business area, producing mining drilling equipment and cutting tools.

In 1956, registered the trademark "Palbit," allowing the international path of the brand, previously known as "Minas e Metalurgia" (Mines and Metallurgy). This move marked the beginning of Palbit's pioneering path in the cemented carbide market. Since then, Palbit has continued to innovate, developing new grades and applications for cemented carbide tools.

Advancements in Coatings and Material Science

The future of cemented carbide will also see significant advancements in the field of coatings and material science.

Palbit continues to explore new and improved coatings that can further enhance the wear and heat resistance of cemented carbide tools. This will lead to even greater efficiencies, reduced downtime, and extended tool life in various manufacturing processes.

Palbit continues to explore new and improved coatings that can further enhance the wear and heat resistance of cemented carbide tools. This will lead to even greater efficiencies, reduced downtime, and extended tool life in various manufacturing processes.

Looking Ahead

As cemented carbide enters its second century, the focus will be on further improving sustainability, refining recycling processes and exploring new materials and technologies to meet the ever-evolving demands of the market.

Palbit remains at the forefront of these efforts, dedicated to driving innovation and tooling for you.

Palbit remains at the forefront of these efforts, dedicated to driving innovation and tooling for you.

The Impact on Industry 4.0

Cemented carbide will play an essential role in shaping the future of manufacturing, especially with the advent of Industry 4.0 and the increased use of automation and digitalization.

Palbit's continued innovation in cemented carbide tools will contribute significantly to the development of advanced manufacturing techniques, such as additive manufacturing, micro-machining, and the integration of AI and robotics.

As industries continue to evolve and adopt new technologies, cemented carbide tools will remain a critical component in enabling precision, speed and efficiency in the manufacturing processes of tomorrow.

Palbit's continued innovation in cemented carbide tools will contribute significantly to the development of advanced manufacturing techniques, such as additive manufacturing, micro-machining, and the integration of AI and robotics.

As industries continue to evolve and adopt new technologies, cemented carbide tools will remain a critical component in enabling precision, speed and efficiency in the manufacturing processes of tomorrow.

Future

Cemented carbide has truly shaped the face of modern industry, with Palbit playing an integral role in its development and adoption.

As we celebrate this 100-year milestone, it's essential to look forward and commit to sustainable practices and continued innovation to ensure that cemented carbide remains a vital cutting tool material for the industries of tomorrow.